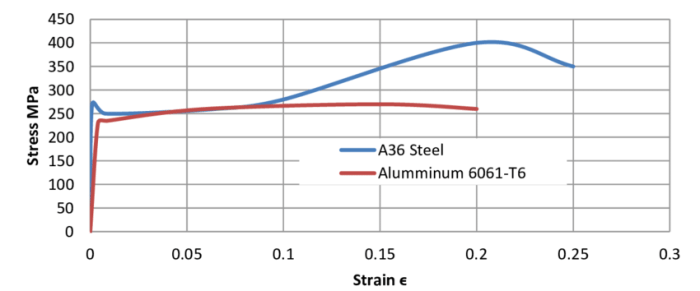

Stress strain curve a36 steel – Unveiling the mechanical properties of A36 steel, the stress-strain curve takes center stage, offering a captivating exploration into the intricate relationship between stress and strain. Delving into the depths of this enigmatic curve, we uncover the secrets of A36 steel’s tensile strength, yield strength, and elongation, revealing its suitability for a wide range of applications.

The stress-strain curve of A36 steel, a visual representation of its mechanical behavior, provides invaluable insights into its elastic and plastic deformation, yield point, ultimate tensile strength, and fracture point. These parameters hold the key to understanding how A36 steel responds to external forces, making it an indispensable tool for engineers and designers.

Mechanical Properties of A36 Steel

A36 steel is a low-carbon steel with a wide range of applications in construction and manufacturing. It is known for its strength, ductility, and weldability. The mechanical properties of A36 steel can vary depending on its heat treatment and composition.

Tensile Strength

Tensile strength is the maximum stress that a material can withstand before it fails under tension. For A36 steel, the tensile strength ranges from 580 to 800 MPa (84,000 to 116,000 psi), depending on its heat treatment. Annealed A36 steel has a lower tensile strength than normalized or quenched and tempered A36 steel.

Yield Strength

Yield strength is the stress at which a material begins to deform plastically. For A36 steel, the yield strength ranges from 360 to 550 MPa (52,000 to 80,000 psi). Annealed A36 steel has a lower yield strength than normalized or quenched and tempered A36 steel.

Elongation

Elongation is the amount of plastic deformation that a material undergoes before it fails. For A36 steel, the elongation ranges from 20 to 30%. Annealed A36 steel has a higher elongation than normalized or quenched and tempered A36 steel.The following table summarizes the mechanical properties of A36 steel in different conditions:| Heat Treatment | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) ||—|—|—|—|| Annealed | 580-650 | 360-400 | 25-30 || Normalized | 650-750 | 400-450 | 20-25 || Quenched and Tempered | 750-800 | 450-550 | 15-20 |

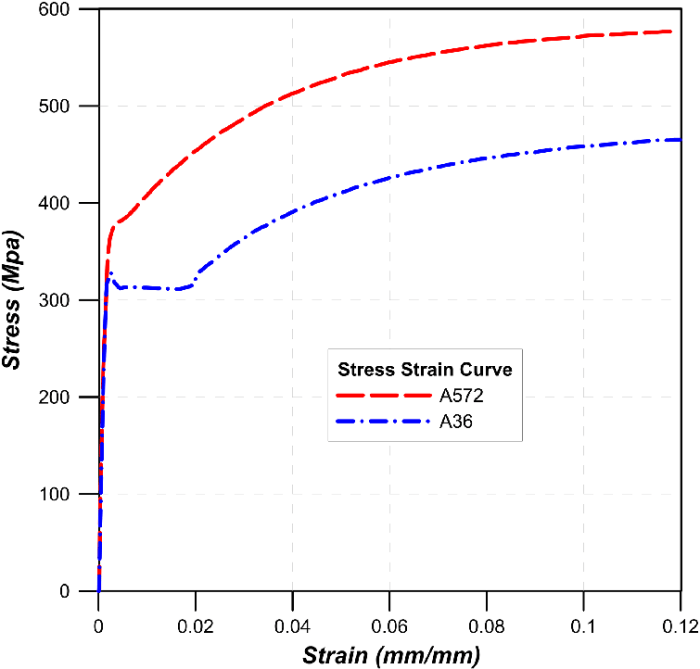

Stress-Strain Curve of A36 Steel

The stress-strain curve of A36 steel is a graphical representation of the relationship between stress and strain. It is a valuable tool for understanding the mechanical properties of A36 steel and predicting its behavior under load.

The stress-strain curve for A36 steel can be divided into three distinct regions:

Elastic Region

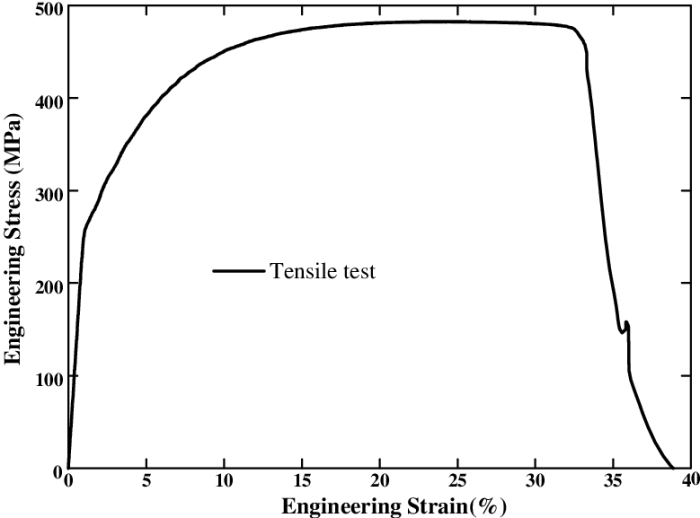

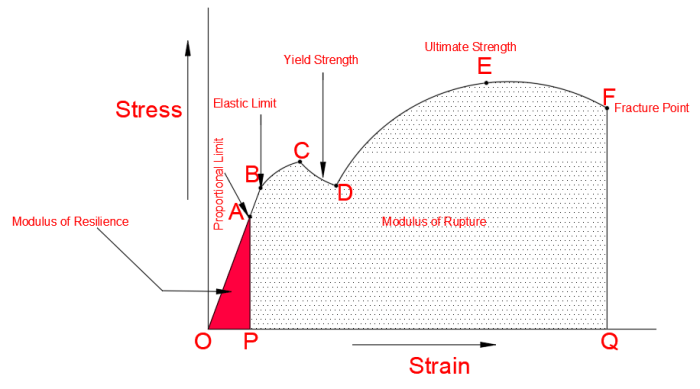

In the elastic region, the stress-strain curve is linear. This means that the material obeys Hooke’s law, which states that stress is directly proportional to strain. The slope of the elastic region is known as the modulus of elasticity, or Young’s modulus.

Yield Point

The yield point is the point on the stress-strain curve where the material begins to deform plastically. This means that the material will continue to deform even if the stress is removed.

Plastic Region

In the plastic region, the stress-strain curve is no longer linear. This means that the material is no longer obeying Hooke’s law. The plastic region is characterized by a region of necking, where the material begins to thin out in a localized area.

Ultimate Tensile Strength

The ultimate tensile strength is the maximum stress that the material can withstand before it fractures.

Fracture Point

The fracture point is the point on the stress-strain curve where the material fractures. This is the point at which the material can no longer withstand the applied load.

The stress strain curve of A36 steel is a valuable tool for understanding the mechanical properties of this material. For more information on the nuances of language, you can refer to the Wordly Wise Book 8 Lesson 11 . This resource provides insightful explanations and exercises that can enhance your vocabulary and comprehension skills.

Returning to the topic of stress strain curve of A36 steel, it’s important to note that the curve provides insights into the material’s yield strength, ultimate tensile strength, and other key mechanical properties.

The stress-strain curve for A36 steel is shown below.

[Image of the stress-strain curve for A36 steel]

Factors Affecting the Stress-Strain Curve

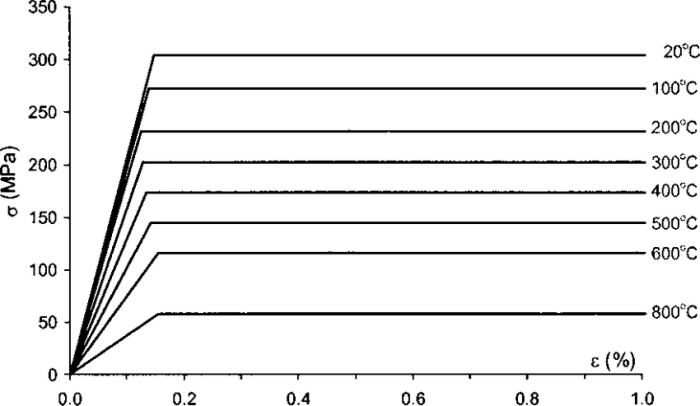

The stress-strain curve of A36 steel can be significantly influenced by various factors, including temperature, strain rate, and grain size. Understanding the effects of these factors is crucial for optimizing the mechanical properties of A36 steel in different applications.

Temperature

Temperature plays a vital role in shaping the stress-strain curve. As temperature increases, the yield strength and ultimate tensile strength of A36 steel generally decrease. This is because elevated temperatures promote atomic diffusion and weaken the interatomic bonds, making the material more susceptible to plastic deformation.

Conversely, at lower temperatures, the material becomes stronger and more brittle due to reduced atomic mobility.

Strain Rate, Stress strain curve a36 steel

Strain rate refers to the rate at which the material is deformed. Higher strain rates result in higher yield strength and ultimate tensile strength. This is because the material has less time to undergo plastic deformation before it fractures. Conversely, lower strain rates allow for more time for plastic deformation, leading to lower yield strength and ultimate tensile strength.

Grain Size

Grain size also affects the stress-strain curve. Smaller grain sizes typically result in higher yield strength and ultimate tensile strength. This is because smaller grains hinder dislocation movement, making the material more resistant to plastic deformation. Conversely, larger grain sizes facilitate dislocation movement, leading to lower yield strength and ultimate tensile strength.

Applications of A36 Steel

A36 steel is a versatile and widely used construction material due to its combination of strength, weldability, and affordability. It is commonly employed in various industries, including:

- Construction:A36 steel is utilized in structural components of buildings, bridges, and other infrastructure projects due to its ability to withstand high loads and resist deformation.

- Automotive:A36 steel is used in automotive frames, bumpers, and other components that require a balance of strength and formability.

- Machinery:A36 steel is employed in the construction of machinery parts, such as gears, shafts, and housings, due to its durability and resistance to wear.

- Energy:A36 steel is used in the construction of pipelines, pressure vessels, and other components in the energy industry due to its ability to withstand high pressures and temperatures.

A36 steel’s suitability for these applications stems from its mechanical properties and stress-strain behavior. Its high yield strength and ultimate tensile strength provide the necessary strength to withstand loads and stresses. The material’s ductility, as indicated by its elongation at break, allows it to deform without fracturing, ensuring structural integrity under varying conditions.For

instance, in the construction industry, A36 steel’s ability to withstand high loads makes it ideal for use in load-bearing structures such as beams, columns, and trusses. In the automotive industry, its combination of strength and formability allows it to be shaped into complex components that meet safety and performance requirements.

Questions Often Asked: Stress Strain Curve A36 Steel

What is the significance of the yield point on the stress-strain curve?

The yield point represents the transition from elastic to plastic deformation, indicating the point at which permanent deformation occurs.

How does the strain rate affect the stress-strain curve?

Increasing the strain rate generally leads to a higher yield strength and ultimate tensile strength, as well as a reduced elongation.

What are the common applications of A36 steel?

A36 steel finds applications in bridges, buildings, ships, vehicles, and various other structural components.